LAYING OUT THE FUEL SYSTEM

If you’ve read even one post or story on building experimental aircraft then you know about the battle over ignition and injection systems. One camp believes that magnetos have been and will always be the way to go. Some people move in other directions. I am not here to join the debate but merely to highlight how I’ve installed my selection for my aircraft. I am going with the EFII System 32 ignition and injection. This is important because it impacts the way you install the fuel system when compared with the stock Van’s instructions. The main concepts are retained and the spaces utilized for fuel selection, fuels lines, pumps, and filters all remain almost exactly the same. The first two parts of installing the fuel system are installing the fuel selector and then the fuel pumps.

FUEL SELECTOR

I chose the the Andair product for my fuel selector. It is indeed quite popular, but aside from following the crowd, I sincerely appreciate the engineering behind this product. Put simply, they have thought of everything during the design process. There are of course modifications that need to be made in order to accommodate the installation of this modification.

The process started with fabricating a modified cradle for the Andair selector to sit in. It comes with a template to help you locate the pass through hole as well as four holes for mounting with AN bolts.

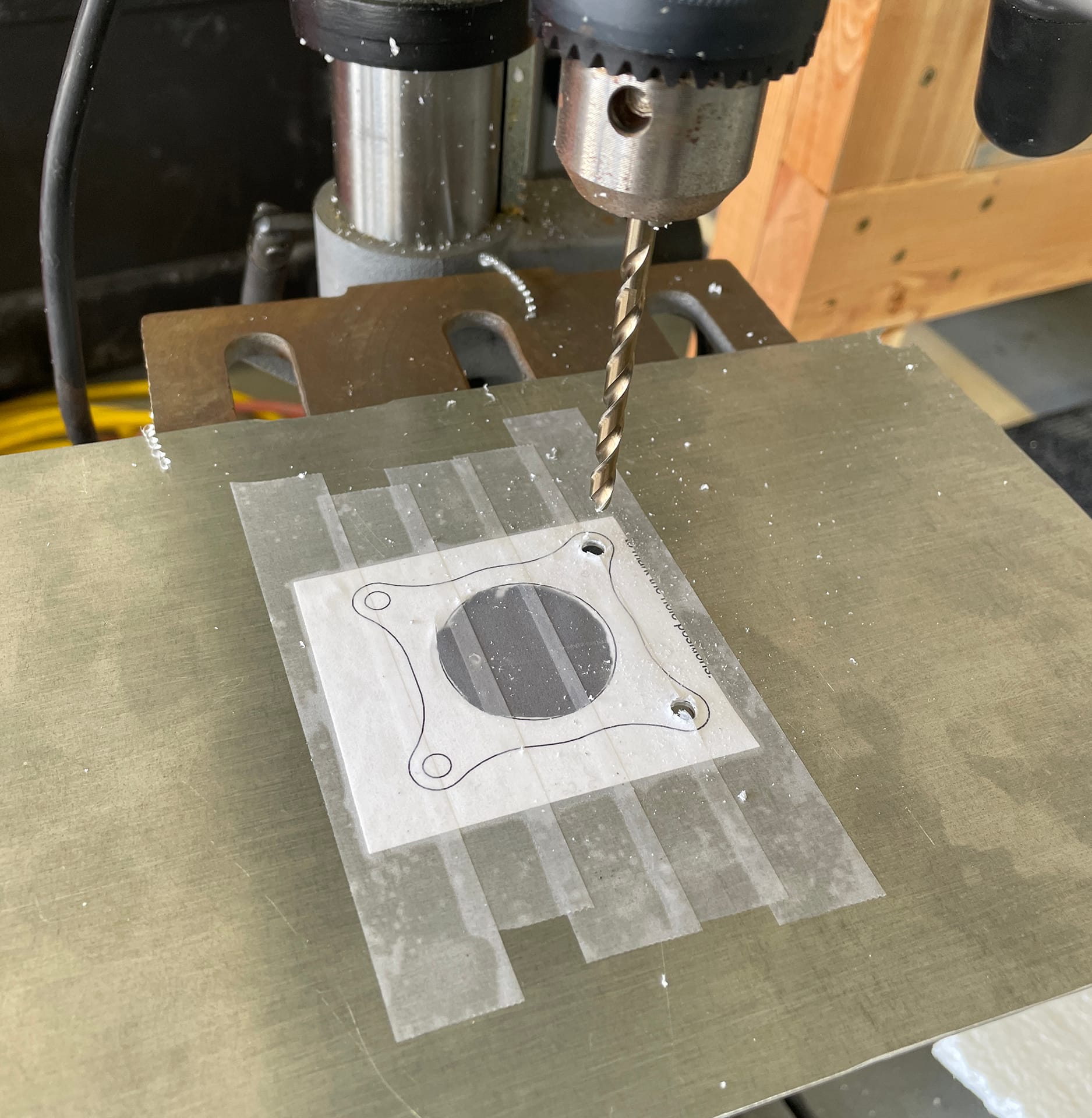

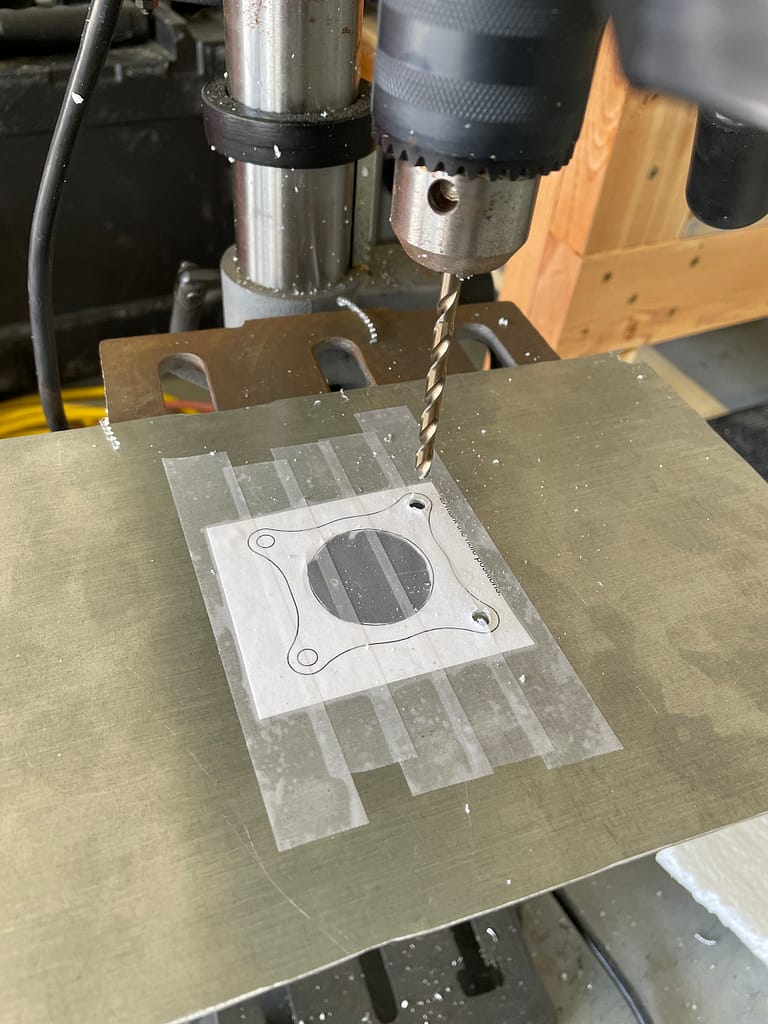

I created the main center hole first and figured I would use that as my “true north” and drill after that. It’s easier to mess up the large central hole so I started there. Next, I taped the template in place and headed to the drill press. This was pretty helpful to get everything lined up – actually mandatory. As you’ll see in a second – the template still wasn’t perfect so I had to redo everything.

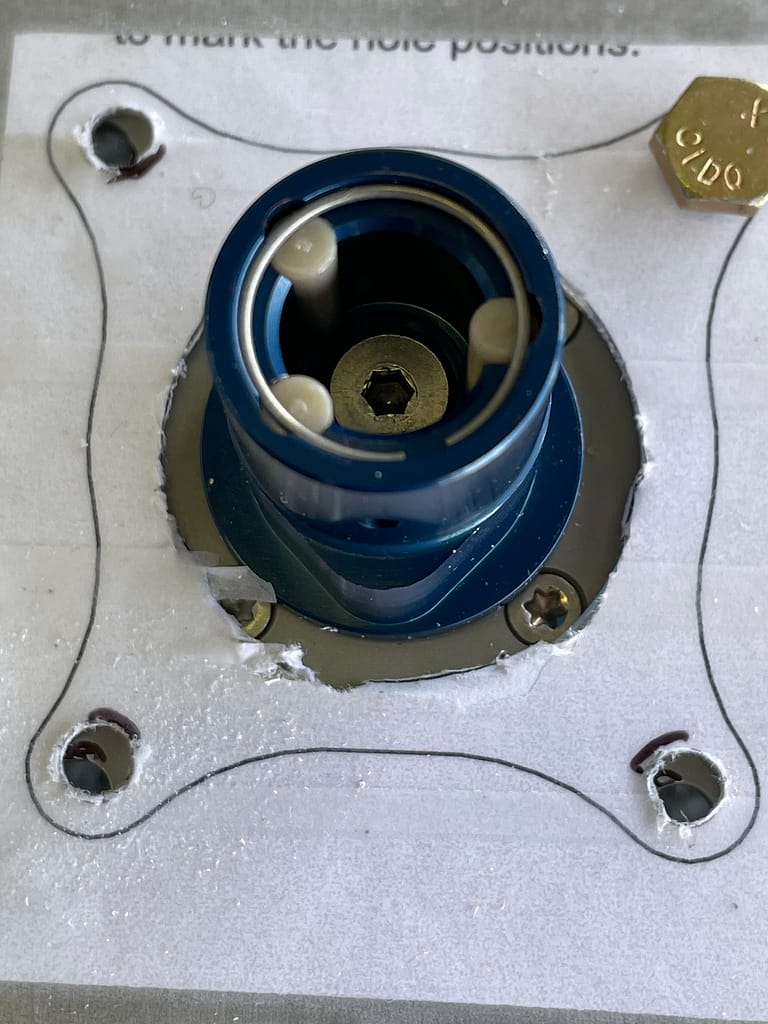

I drilled the template perfectly and it was off substantially. The next time around, I used the template for the outer shape only and sighted in the bolt holes using the actual part itself. NOTE: I did NOT match drill through this part. Bad idea. I marked locations and drilled after the fact. More to come later on the fuel lines.