PREPARING TO ATTACH THE CABIN TOP

Once again, we come across competing schools of thought in the RV-10 universe of builders. I have seen some people prepare their cabin tops prior riveting on the forward fuselage. The instructions provided from Vans have you rivet everything in place prior to sizing the cabin top. While it is impossible to ignore the utility and helpfulness of being able to remove the upper forward fuse during avionics install, I have decided to stick to the program provided by Vans. Step one, carefully performing the upper forward fuse attach. This is certainly one of the jobs where you need two people. I’ve seen many creative solutions for solo builders, but I just can’t imagine a safer or better way than to have a helping hand. With that, we set out to attach the upper forward fuse.

I had to be really careful not to get carried away. The forward most row of rivets is left undone until final attach of the cowling. It’s a bit early, but I’m thinking about using Sky Bolts for this. Quick. Talk me out of it.

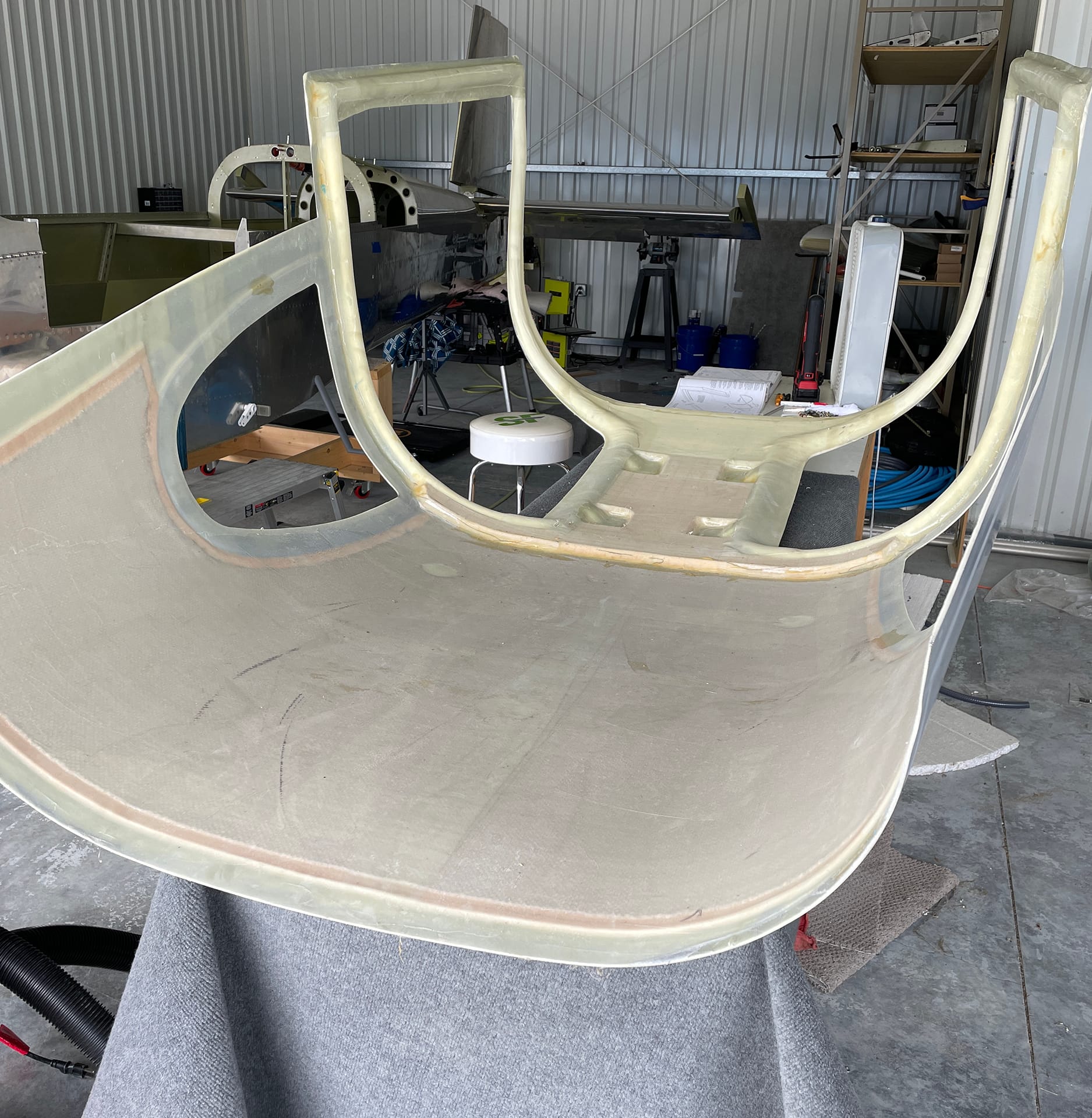

SETTING UP THE CABIN TOP AND INITIAL SIZING CUTS

I found it incredibly helpful to create a level, padded, elevated workspace to perform the initial sizing cuts on the cabin top. Based upon what I have heard elsewhere, I’m on the luckier side that my scribe lines were all visible. I have also heard that this is almost immaterial as they are rather poor guides of final position. All the same, they provided a clear starting point that I cut all of my outer edges and inner windows to. I’ll add another post just on fiberglass tools. It seems that there is a lot of discussion out there about what works best and just like everyone else, I have my own opinions for sure. The only non-negotiable one is face protection.

This is also a time where I am incredibly grateful for those who have come before me. When I began trimming and looking at the fit of the cabin top, I was nervous at how thin the sides were getting. Other builders were able to calm me down a great deal, but even still, it got TIGHT. My only advice is make sure you get a good fit, and sand on. Here are a few final images of what the cabin top looked like during the sanding process and an initial rough fit that wasn’t quite there.